Benchtop UTM (1-100 kN) Products

Benchtop UTM (1-100 kN) Products

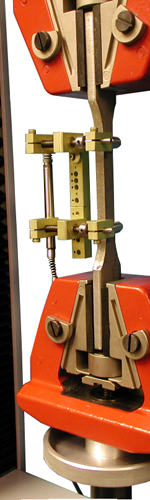

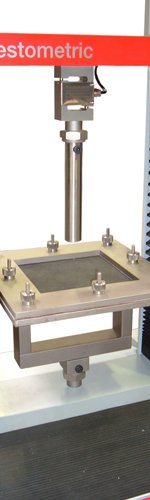

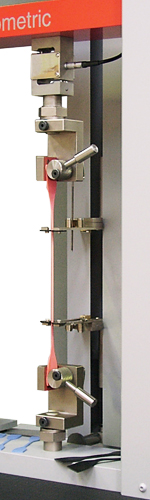

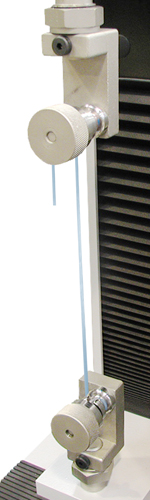

Testometric’s Universal Testing Machines (UTMs) are designed to cater to a wide range of materials and applications, from research labs to routine quality control in various industries. The machines in the 1 kN to 1000 kN range are renowned for their precision, versatility, and ease of use.

Key Features:

- Wide Capacity Range: Models available from 1 kN to 1000 kN, suitable for testing a variety of materials including geotextile, fabrics, adhesives, composites, metals, textiles, plastics, and more.

- High Precision: Equipped with high-stiffness load frames and advanced electronics to ensure accurate and repeatable results.

- Touch Screen and PC Compatibility: Modern touch screen interface combined with PC compatibility allows for enhanced control and data management using WinTest™ software.

- User-Friendly Interface: Full numeric keypad with tactile buttons and a large, clear matrix display for easy operation and data viewing.

- Automated Testing Capabilities: Features such as automatic specimen break detection, auto-ranging, auto-calibration, and quick rate return enhance testing efficiency and accuracy.

- Comprehensive Data Output: Capable of generating hard copies of test reports including results, statistics, and graphs. Data can also be exported for further analysis.

Benefits:

- Versatile Use: Suitable for a broad range of industries, from aerospace to packaging.

- Enhanced Efficiency: High-speed data collection and processing capabilities reduce testing time.

- Quality Assurance: Ensures products meet industry standards and specifications through rigorous testing.

- Robust Design: Built to withstand heavy usage in industrial environments, ensuring long-term reliability.

SOFTWARE

Comprehensive winTest™ Analysis universal windows software covering tensile, compression, peel, shear, tear, cyclic, creep and multi stage testing. It includes a wide range of industry standard test methods and facility to create and store an unlimited number of further test methods. There is automated storage of all test data and ease of export to other software packages such as word, excel, access and SPC systems for enhanced report generation.

| Column 1 | Column 2 | Column 3 | Column 4 |

|---|---|---|---|

| Average Force | Energy to Break | Density | Plastic Strain Ratio r |

| Average Force / Width | Energy to Yield | Chewiness | Spring Rate Between Forces |

| Bending Modulus | Initial Modulus | Fracturability | Spring Rate Between Deflections |

| Crush Force (Edge) | Force @ Peak | Hardness | Young’s Modulus |

| Deflection @ 1st Collapse | Force @ 1st Collapse | Poisson’s Ratio | Chord Modulus |

| Deflection @ Force (Stage) | Force @ Elongation | Plastic Strain Ratio r | Tangential Modulus @ Strain |

| Dynamic Co-eff of Friction | Force @ Proof | Spring Rate Between Forces | Tangential Modulus @ Stress |

| Elongation @ Break | Force after Stage | Spring Rate Between Deflections | Secant Modulus @ Strain |

| Energy to Break | Lowest Force | Young’s Modulus | Secant Modulus @ Stress |

| Energy to Yield | Seam Opening Force | Chord Modulus | Strain @ Limit of Proportionality |

| Initial Modulus | Seamed Strength | Tangential Modulus @ Strain | Force @ Rupture |

| Force @ Peak | Static Co-eff of Friction | Tangential Modulus @ Stress | Strain @ Rupture |

| Force @ 1st Collapse | Strain @ Break | Secant Modulus @ Strain | Average of 5 Highest Peaks |

| Force @ Elongation | Strain @ Force (Load Cycle) | Secant Modulus @ Stress | Bend. Strength @ Peak |

| Force @ Proof | Strain @ Force (Return Cycle) | Strain @ Limit of Proportionality | Bursting Strength |

| Force after Stage | Strain @ Force (Stage) | Force @ Rupture | Average Peaks (Selected Region) |

| Lowest Force | Stress @ Peak | Strain @ Rupture | Percentage Reduction of Area |

| Seam Opening Force | Stress @ Proof | Average of 5 Highest Peaks | Secant Stiffness |

| Seamed Strength | Stress @ Strain | Bend. Strength @ Peak | Stress @ % Height |

| Static Co-eff of Friction | Stress @ Yield | Bursting Strength | Force @ Time |

| Strain @ Break | T.E.A. | Average Peaks (Selected Region) | Deflection @ Time |

| Strain @ Force (Load Cycle) | Tenacity | Percentage Reduction of Area | Time to Peak |

| Strain @ Force (Return Cycle) | Transverse Rupture Strength | Secant Stiffness | Time to Failure |

| Strain @ Force (Stage) | Unseamed Strength | Stress @ % Height | LOP |

| Stress @ Peak | Young’s Modulus | Force @ Time | MOR |

| Stress @ Proof | Chord Modulus | Deflection @ Time | Strain to LOP |

| Stress @ Strain | Tangential Modulus @ Strain | Time to Peak | Strain to MOR |

| Stress @ Yield | Tangential Modulus @ Stress | Time to Failure | Ym |

| T.E.A. | Secant Modulus @ Strain | LOP | Average of 5 Highest Peaks |

| Tenacity | Secant Modulus @ Stress | MOR | Spring Rate Between Forces |

| Transverse Rupture Strength | Strain @ Limit of Proportionality | Strain to LOP | Density |

| Unseamed Strength | Force @ Rupture | Strain to MOR | Chewiness |

| Young’s Modulus | Strain @ Rupture | Ym | Hardness |

| Chord Modulus | Average Peaks (Selected Region) | Average of 5 Highest Peaks | Poisson’s Ratio |

| Tangential Modulus @ Strain | Percentage Reduction of Area | Spring Rate Between Deflections | Plastic Strain Ratio r |

| Tangential Modulus @ Stress | Spring Rate Between Forces | Density | Spring Rate Between Deflections |

| Secant Modulus @ Strain | Spring Rate Between Deflections | Chewiness | Young’s Modulus |

| Secant Modulus @ Stress | Chewiness | Hardness | Chord Modulus |

| Strain @ Limit of Proportionality | Fracturability | Poisson’s Ratio | Tangential Modulus @ Strain |

| Force @ Rupture | Hardness | Plastic Strain Ratio r | Tangential Modulus @ Stress |

| Strain @ Rupture | Plastic Strain Ratio r | Spring Rate Between Forces | Secant Modulus @ Strain |

| Average of 5 Highest Peaks | Spring Rate Between Deflections | Density | Secant Modulus @ Stress |

| Bend. Strength @ Peak | Young’s Modulus | Chewiness | Strain @ Limit of Proportionality |

| Bursting Strength | Average Peaks (Selected Region) | Hardness | Force @ Rupture |

| Percentage Reduction of Area | Poisson’s Ratio | Strain @ Rupture |

| Applications | ||

|---|---|---|

| Aerospace | Adhesives | Packaging |

| Automotive | Food | Cord and Rope |

| Cable and Wire | Pipe | Elastic |

| Clothing | Adhesive tape | Geotextiles |

| Containers | Credit Cards | Medical |

| Military | Constructions | Rubber |

| Bedding | Cargo Restraints | GRC |

| Toys | Concrete | Rope & Nets |

| Fibre | Metals | Insulation |

| Foam | Furniture | Footwear |

| Timber | Springs | Plastic film and sheet |

| Wood based Panel | Yarn & Cord | Corrugated board & Boxes |

Each model is tailored to provide optimal performance for specific testing requirements, ensuring that you have the right tool for your application.