Description

Automotive Testing Solutions

Dynisco MFI Tester: Evaluates the Melt Flow Index (MFI) of polymers, which helps determine flow characteristics during processing. This data is essential for quality control and material selection, ensuring that automotive components meet stringent performance and reliability standards.

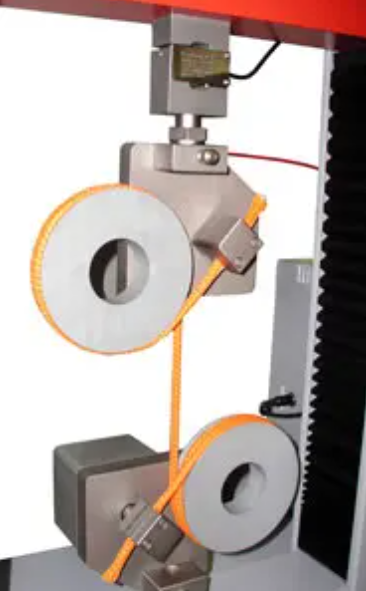

Testometric delivers advanced testing systems for the automotive industry, engineered to assess the mechanical properties of materials and components used in vehicles. These systems are equipped with precision load cells, extensometers, and custom fixtures to perform tensile, compression, flexural, peel, shear, and impact testing across a wide range of automotive materials including plastics, rubbers, metals, foams, composites, textiles, and adhesives.

Designed for both R&D and quality control environments, Testometric systems ensure repeatable accuracy, high-throughput testing, and full compliance with international standards such as ASTM, ISO, and DIN. Common applications include testing of seat belt webbing, elastomers, interior trim, structural adhesives, foam panels, coatings, wires, and fasteners.

Typical Test Standards in Automotive Applications:

Tensile, Compression & Flexural Testing:

- ASTM D638 / ISO 527 – Tensile properties of plastics and composites

- ASTM D695 / ISO 604 – Compressive properties of plastics

- ASTM D790 / ISO 178 – Flexural properties of plastics and composites

- ASTM E8 – Tensile testing of metallic materials

- ISO 6892 – Tensile test of metallic materials

- ASTM A370 – Mechanical testing of steel products

Rubber & Elastomer Testing:

- ASTM D412 / ISO 37 – Tensile properties of rubber

- ASTM D2240 / ISO 7619-1 – Hardness testing of rubber (Shore A, D)

Adhesion, Peel, and Shear Testing:

- ASTM D903 – Peel or stripping strength of adhesive bonds

- ASTM D1876 – T-peel strength of flexible bonded materials

- ASTM D1002 – Lap shear strength of adhesives

- ISO 11339 – T-peel test for flexible to rigid bond

Impact & Toughness Testing:

- ASTM D256 / ISO 179 – Izod impact strength of plastics

- ASTM D6110 / ISO 180 – Charpy impact resistance of plastics

- ASTM E23 / ISO 148 – Impact testing of metallic materials

Friction, Wear & Abrasion:

- ASTM D1894 / ISO 8295 – Coefficient of friction for plastic films

- ASTM D4060 – Abrasion resistance (Taber method)

Textiles & Webbing (e.g., Seat Belts):

- ASTM D5034 / ISO 13934-1 – Tensile strength of textile fabrics

- FMVSS 209 – Seat belt webbing strength and elongation

These solutions are designed to meet the demanding requirements of the automotive industry, ensuring optimal material performance and component reliability in both standard and high-performance applications.