Description

Automotive Testing Solutions

Testometric Solutions

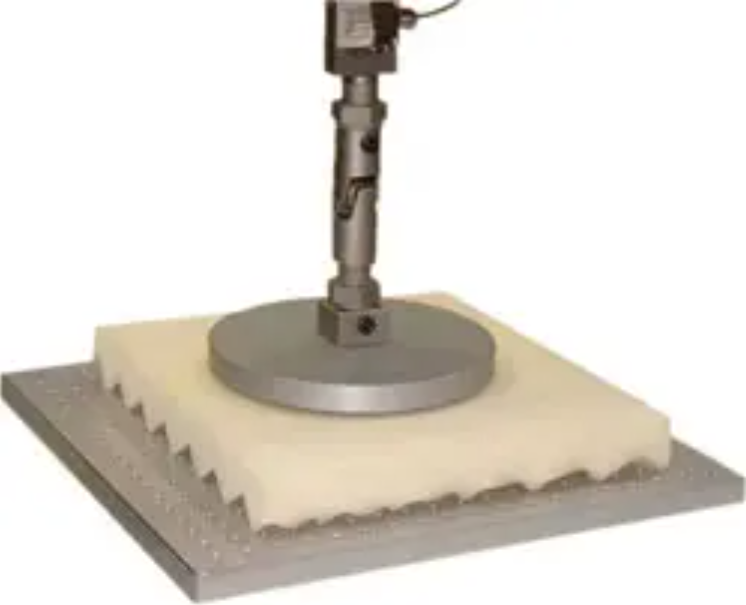

Testometric provides dedicated test systems designed to assess the quality and reliability of materials and components used in the automotive industry. These systems feature:

- Specialized Test Fixtures: Custom-designed to handle various automotive materials and components, ensuring accurate and reliable testing.

- Advanced Software: Developed to comply with relevant international standards, offering detailed analysis and reporting capabilities.

Testometric’s solutions are employed by industry leaders such as Volvo, Rolls-Royce, and Cranfield Impact Centre. The Cranfield Impact Centre, renowned for its expertise in Formula 1 testing, is the only FIA-approved center globally authorized to conduct crash testing of critical safety components, including halos, safety locks, latches, and seat belts. This approval underscores their capability to meet the stringent safety standards required for high-performance motorsports.

Dynisco Solutions

- Dynisco Capillary Rheometer: Measures the flow properties of polymers through a capillary die, providing detailed insights into viscosity and shear behavior. This is critical for understanding how polymers will perform during automotive component processing.

- Dynisco MFI Tester: Evaluates the Melt Flow Index (MFI) of polymers, which helps determine flow characteristics during processing. This data is essential for quality control and material selection, ensuring that automotive components meet stringent performance and reliability standards.

These solutions are designed to meet the demanding requirements of the automotive industry, ensuring optimal material performance and component reliability in both standard and high-performance applications.