Description

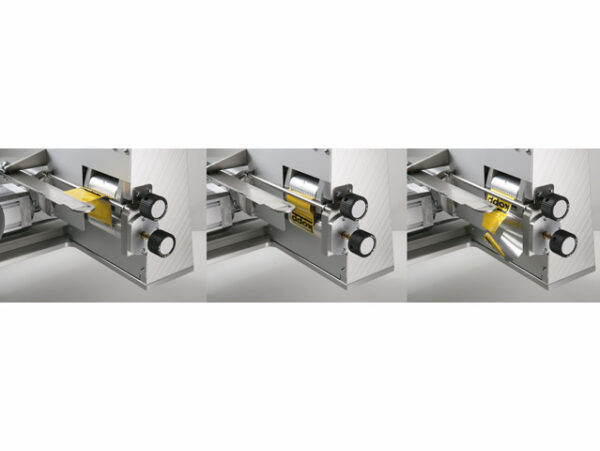

For sealing tests with subsequent tensile testing (hot tack or cold tack) on sealable flexible packaging materials.

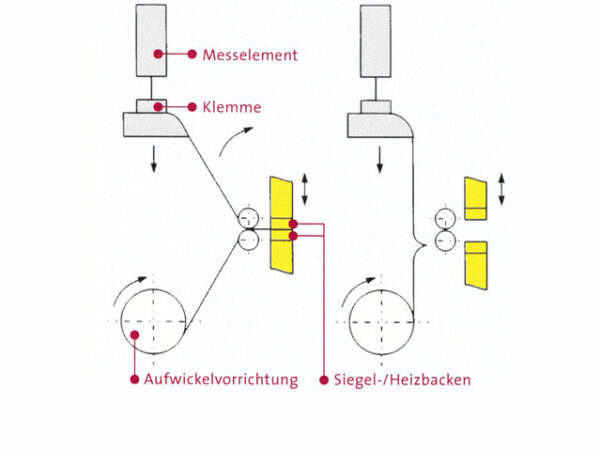

- For measuring sealing strength immediatly after sealing (hottack)

- For measuring sealing strength after defined cooling time (coldtack)

- Usable as a laboratory sealer

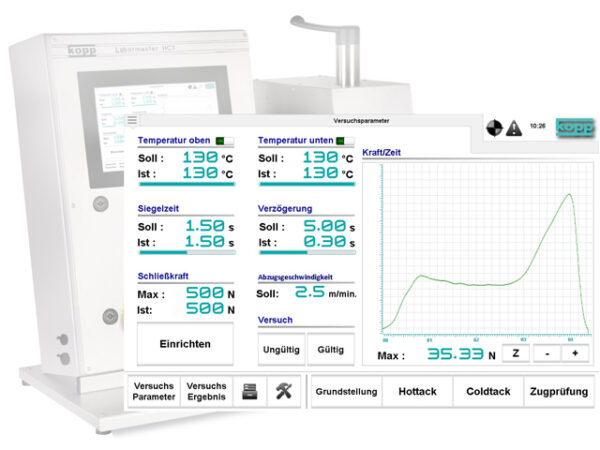

- Precisely adjustable, calibrated sealing parameters and test parameters – sealing time, sealing temperature at the top, sealing temperature at the bottom, sealing force (closing force), withdrawal time (cooling time) and withdrawal rate (pull-off speed)

- High accuracy and maximum reproducibility of all parameters

- Exchangeable sealing bars with different surfaces (smooth, grooved, corrugated)

- Meets all requirements of a test device according to DIN ISO

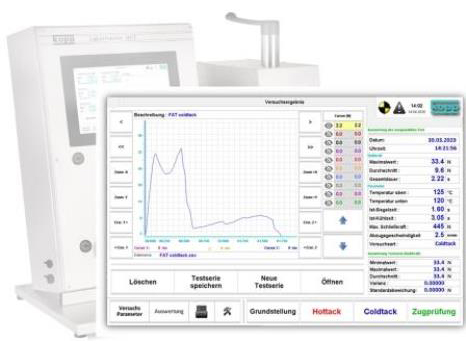

- Displaying of the meassuerd force as a graph

- Test series with up to 10 curves can be displayed

- Easy operation and clear presentation on the touch panel

- USB and Ethernet interface for saving the test series

| Details | |

|---|---|

| Sealing width | 5mm, 10mm or 20mm depending on the sealing bars |

| Sealing length | 100mm or 200mm depending on the sealing jaws |

| Sealing surface | smooth, grooved, corrugated depending on the sealing bars |

| Specimen width | up to 60mm |

| Sealing time adjustable | up to 99.99sec. |

| Withdrawal time adjustable | up to 99.99sec. |

| Sealing temperature adjustable | up to 260°C regulated separately top and bottom |

| Sealing force | up to 1800N |

| Withdrawal rate | up to 12m/Min |

| Sealing system | Thermal contact heat sealing system |

| Force measurement method (hottack) |

DIN 55571-2 method-A 21 |

All data are approximate only.

Datavis Visualzation for Labormaster

Softwaretool DATAVIS for Windows(r) has been designed for a quick and easy visualzation of the measurement data taken from the Labormaster. Test parameters and force/time curves of test series are displayed on the PC screen and can be printed.

Sample cutter

Manual cutter with two parallel cutting blades. Width 45 mm others on request.

Mobile trolly for Labormaster

to placeing the Laboratory Sealer SGPE or the sealing strength tester Labormaster

Cover hood for laboratory sealer

Sturdy cover to protect the laboratory sealer whern it ist not used

Longitudinally grooved sealing bars

in widths of 5 mm, 10 mm and 20 mm – PTFE-coated or uncoated

Cross grooved sealing bars for laboratory sealer SGPE and Labormaster

in widths of 5 mm, 10 mm and 20 mm – PTFE-coated or uncoated

Corrugated sealing bars for laboratory sealer SGPE and Labormaster

Sealing bars with waffle pattern milling, in widths of 5 mm, 10 mm and 20 mm – PTFE-coated or uncoated

Sealing bar with silicone rubber for laboratory sealer SGPE and Labormaster

for sealing against metal bar (hard against soft). The silicone bar can be heated.

The Labormaster hottack tester has its permanent place in packaging material development for flexible packaging, i.e. for classic plastic films, laminates and composites as well as for coated papers or new sealable, recyclable packaging materials and compostable packaging materials.

During production, the Labormaster is used in the manufacture and refinement of packaging materials for quality assurance.

In addition, the hottack tester Labormaster helps quality control and quality assurance in checking the sealing properties, heat sealability and in determining the optimal processing parameters (sealing window).