Description

For test seals with precisely defined and calibrated parameters.

- Precisely adjustable, calibrated sealing parameters – sealing time, sealing temperature at the top, sealing temperature at the bottom and sealing force (closing force)

- High accuracy and maximum reproducibility of all parameters

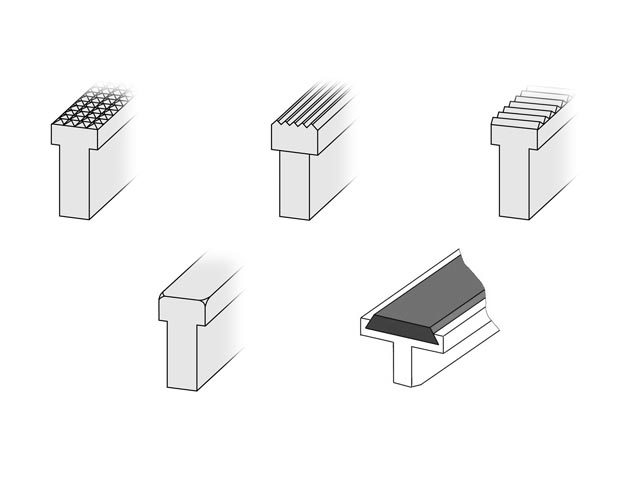

- Exchangeable sealing bars with different surfaces (smooth, grooved, corrugated)

- Meets all requirements of a test device according to DIN ISO

- USB interface for saving the validation data

- Easy operation and clear presentation on the touch panel

| Details | |

|---|---|

| Sealing width | 5mm, 10mm or 20mm depending on the sealing bars |

| Sealing length | 100mm or 200mm depending on the sealing jaws |

| Sealing surface | smooth, grooved, corrugated depending on the sealing bars |

| Sealing time adjustable | up to 99.99sec. |

| Sealing temperature adjustable | up to 260°C regulated separately top and bottom |

| Sealing force | up to 2000N |

| Sealing system | Thermal contact heat sealing system |

All data are approximate only.

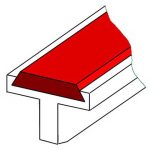

Smooth sealing bars for Laboratory Sealer SGPE and Labormaster

in widths of 5mm, 10mm and 20mm – PTFE-coated or uncoated. Smooth sealing bars are the standard for a variety of seals and seal strength testing.

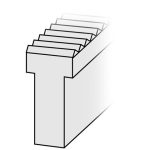

Longitudinally grooved sealing bars for Laboratory Sealer SGPE and Labormaster

in the widths of 5mm, 10mm and 20mm – PTFE-coated and uncoated

Sealing bar with silicone rubber for laboratory sealer SGPE and Labormaster

for sealing against metal bar (hard against soft). The silicone bar can be heated as well.

Cross grooved sealing bars for laboratory sealer SGPE and Labormaster

in widths of 5 mm, 10 mm and 20 mm – PTFE-coated or uncoated

Auflege- und Zuführtisch für Laborsiegelgerät SGPE

zur Auflage der Proben, plan zur Siegelkontaktfläche.

Werksprüfzeugnis (Kalibrierzertifikat)

Durch die Werkskalibrierung werden die Anforderungen für Prüfgeräte nach DIN ISO erfüllt. Die Kalibrierung unserer Geräte kann vor Ort beim Kunden oder bei uns im Haus durchgeführt werden.

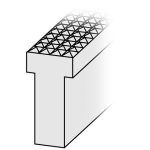

Corrugate sealing bars for laboratory sealer SGPE an Labormaster

Sealing bars with waffle pattern milling, in widths of 5mm, 10mm and 20mm – PTFE coated or uncoated

Mobile trolly for Laboratory Sealer

to placing the Laboratory Sealer SGPE or the sealing strength tester Labormaster

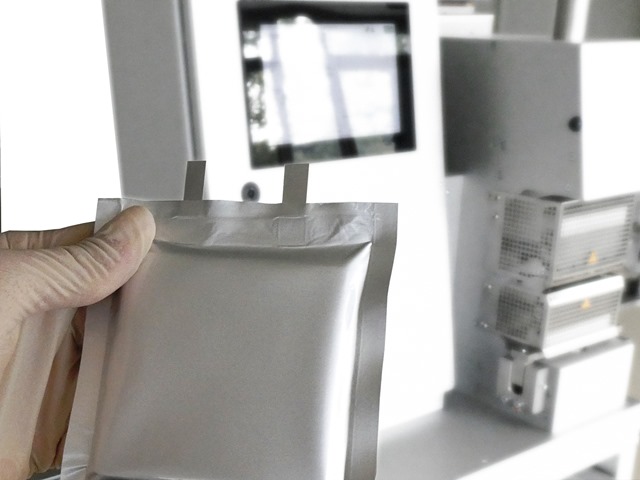

The KOPP laboratory sealer SGPE is used in research and development (R&D), quality testing, quality assurance, laboratory, material testing for the development and testing of foils, bio-foils, composites, sealing lacquers, sealing media.In packaging development, the laboratory sealer is used to build prototypes, packaging dummies or marketing samples for packaging concepts.

A special field of application for the SGPE laboratory sealing device is the production and development of energy cells and battery pouches.